Alternating Current

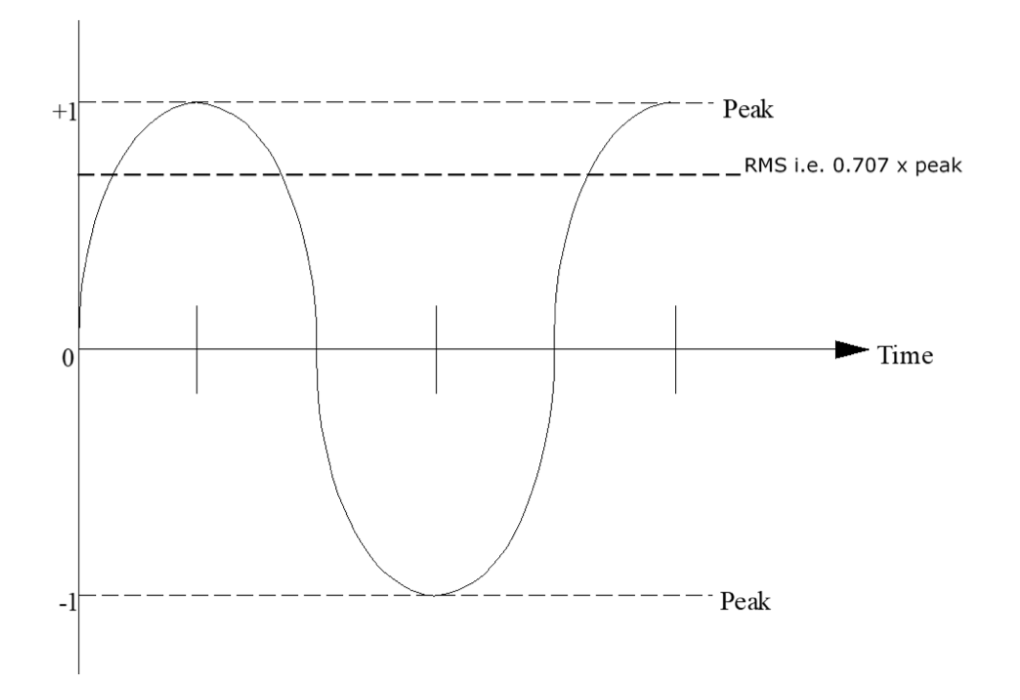

Alternating current (AC) changes in strength and direction. For all practical purposes, the AC waveform is preferred for locating surface flaws. A.C. does not penetrate deeply into the metal but produces a high density field near the surface of a ferromagnetic conductor, this characteristic is called the skin effect and will emphasise surface breaking discontinuities, e.g. fatigue or stress induced cracks. The skin effect is caused by the concentration of eddy currents near the surface of the specimen; eddy currents are only produced by an alternating current. The symbol sometimes encountered for AC is ~ (sine wave).

If surface breaking flaws are of prime consideration for detection, the operator will not be distracted by the presence of indications from sub-surface flaws.

Other advantages of AC include:

- Current at required values can normally be obtained directly from the mains supply, or via simple transformers.

- AC equipment is relatively inexpensive, are easy to maintain and have basic operating characteristics.

- Due to the current form fluctuation (negative to positive), magnetic particles will vibrate and readily align themselves to flux leakages; this enhances the definition of discontinuity indications.

- If after magnetisation the current is reduced to zero via a rheostat or step down device the component is automatically demagnetised.

Disadvantages: • The main disadvantage of A.C. is that it will only detect surface discontinuities with any degree of reliability.